| Sr. No. |

FEATURES |

MERITS |

| A |

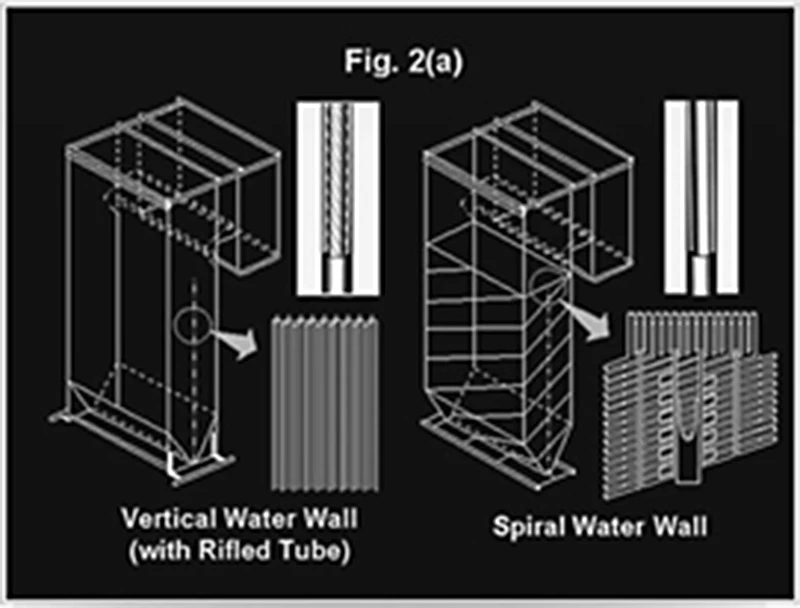

FURNACE WALL |

| |

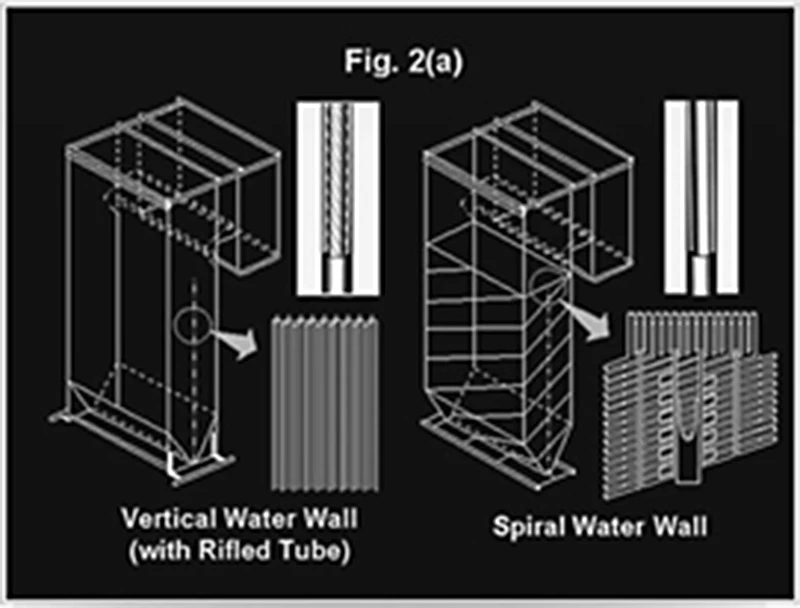

- Vertical wall construction as standard

- MHI has largest number of sliding pressure vertical wall supercritical units in operation

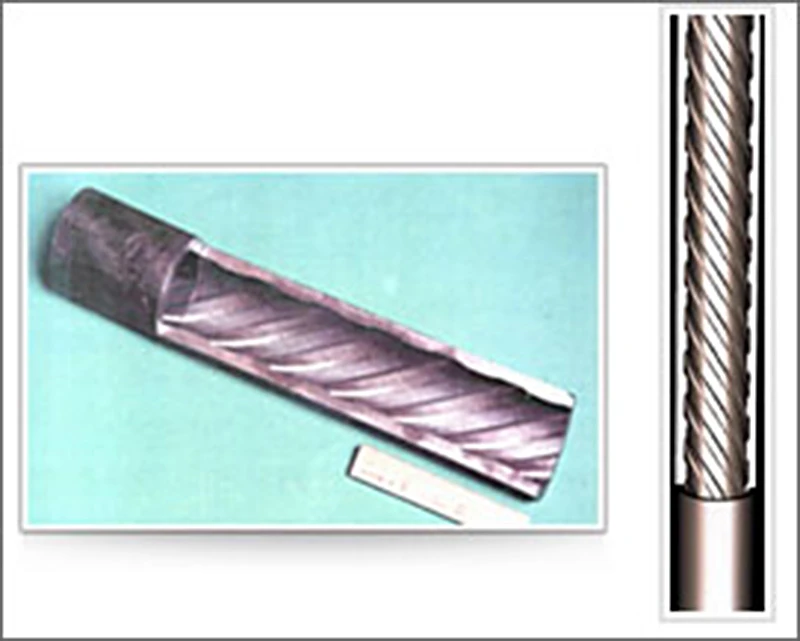

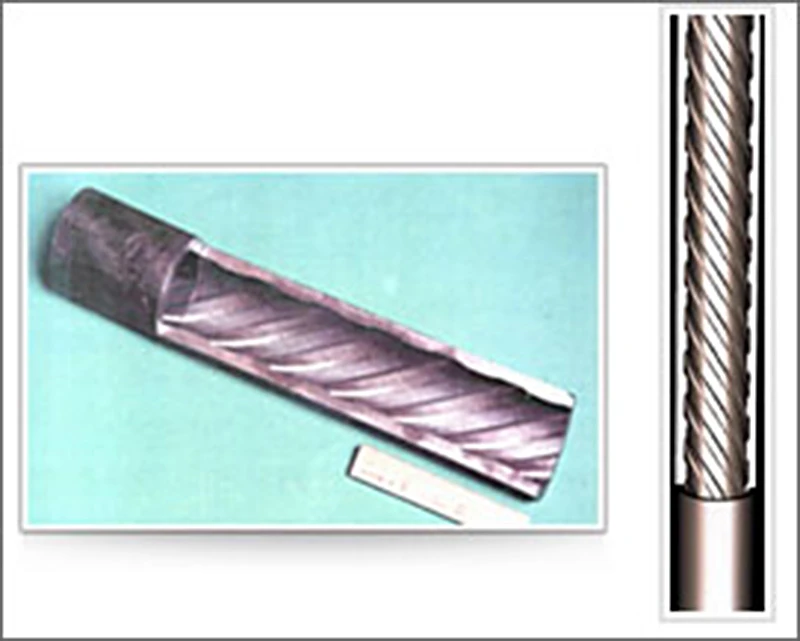

- Rifled tube construction In high heat flux zone

|

- Easier manufacturing and simpler construction

- Low mass flux compared to spiral wall and hence lesser pressure drop

- Lesser field joints

- Less slag accumulation

- Less thermal stresses

- Simpler supporting arrangement

|

| |

|

|

| B |

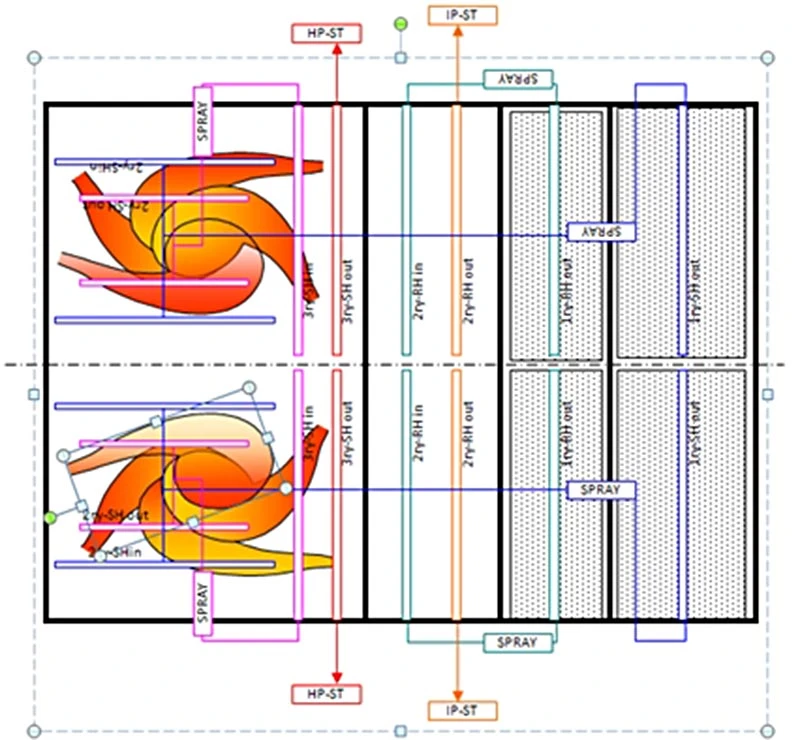

FIRING ARRANGEMENT |

| |

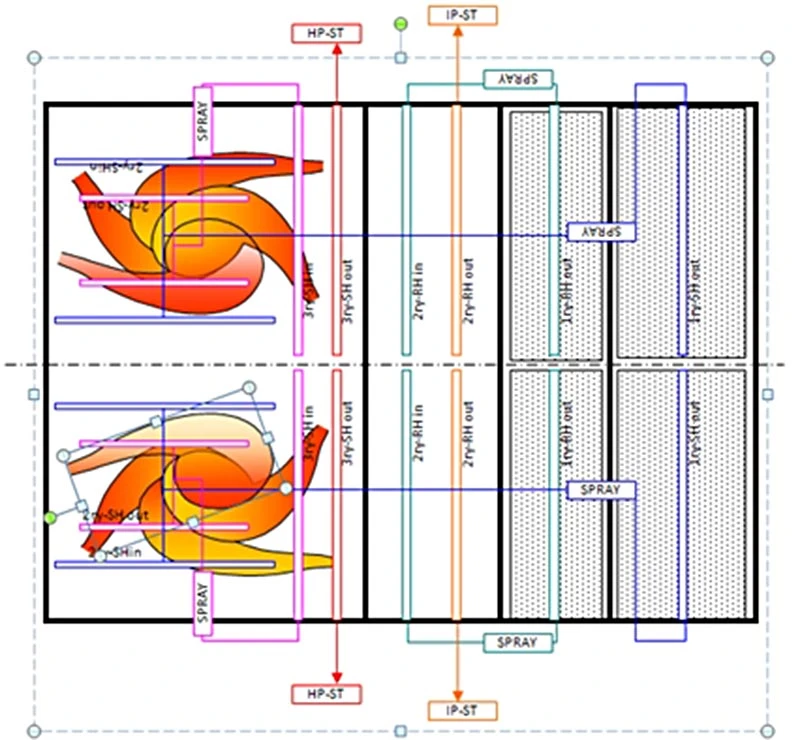

Circular corner firing (CCF) with twin fire vortex as standard |

- Less steam temperature imbalance between left and right leads

- Uniform heat flux in the furnace

- Less burner heat input

|

| |

|

| C |

COAL FIRING SYSTEM |

| |

Use of MACT (Mitsubishi Advanced Combustion Technology) with APM (Advanced Pollution Minimum) burner and additional air port |

- High ignition ability under low O2 condition

- Reduced NOx emmisions

- Reduced unburn carbon loss

- Low excess air (15%) increases boiler efficiency

|

| D |

R H TEMPERATURE CONTROL |

| |

- Use of gas biasing damper in the second pass as primary control

- Additional tilting mechanism for burners as a secondary control

- Interstage attemperation as emergency control

|

- Pressure control of RH temperature is achieved

- No RH spray under steady state operation

|

| E |

SUPERHEATER CONFIGURATION |

| |

- Use of three stage superheater

- Use of inter stage attemperation

|

Better SH steam temperature control |

| F |

USE OF ADVANCED RELIABLE MATERIALS FOR HIGH TEMPERATURE APPLICATIONS |

| |

- CC2328 (SA213 UNS S30432) in SH & RH applications

- Above material has been devloped by MHI in collaboration with tube manufacturers for supercritical and ultra supercritical boilers

- Non-usage of T91 materials in heating zone

|

- Better creep properties

- Reduced steam oxidation leading to higher availability as compared to T91 materials

|